English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

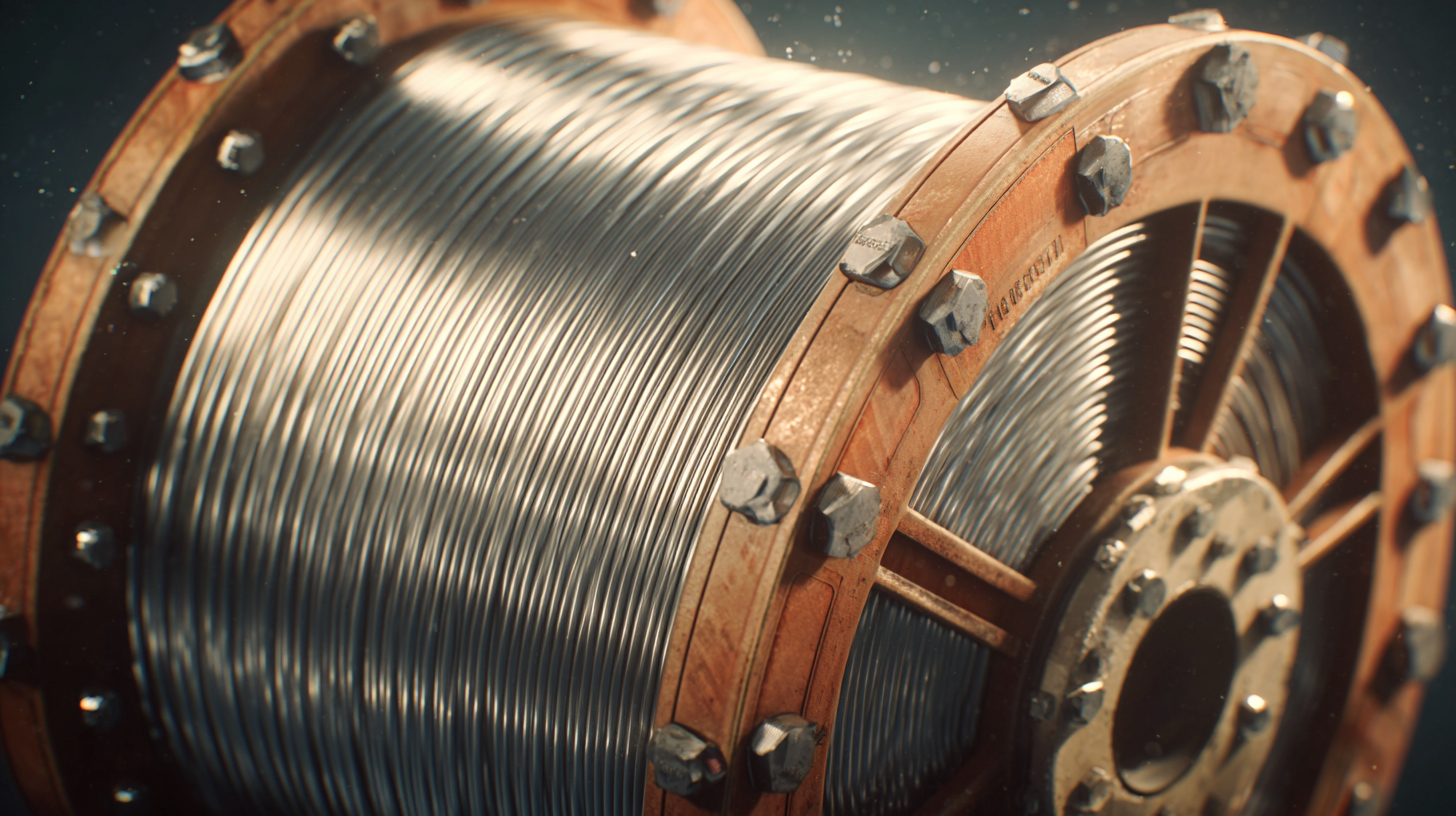

Exploring the 2025 Trends in Steel Cable Spool Technology and Their Impact on Global Procurement Efficiency

As we look ahead to 2025, the landscape of Steel Cable Spool technology is set to undergo significant transformations that could redefine global procurement strategies. With advancements in manufacturing processes and materials, Steel Cable Spools are becoming increasingly efficient and sustainable, aligning with the demands of a rapidly evolving market. This blog will explore the cutting-edge trends in this essential product category, delving into how innovations in design and production not only enhance the performance of Steel Cable Spools but also contribute to overall supply chain effectiveness. By leveraging China's manufacturing prowess, known for its excellence and global service orientation, businesses can optimize their procurement processes, ensuring that they remain competitive in an ever-changing marketplace. Join us as we investigate these trends and their potential impact on industries worldwide.

As we look ahead to 2025, the landscape of Steel Cable Spool technology is set to undergo significant transformations that could redefine global procurement strategies. With advancements in manufacturing processes and materials, Steel Cable Spools are becoming increasingly efficient and sustainable, aligning with the demands of a rapidly evolving market. This blog will explore the cutting-edge trends in this essential product category, delving into how innovations in design and production not only enhance the performance of Steel Cable Spools but also contribute to overall supply chain effectiveness. By leveraging China's manufacturing prowess, known for its excellence and global service orientation, businesses can optimize their procurement processes, ensuring that they remain competitive in an ever-changing marketplace. Join us as we investigate these trends and their potential impact on industries worldwide.

Advancements in Steel Cable Spool Design: Key Technical Specifications for 2025

In 2025, the evolution of steel cable spool technology is set to redefine procurement efficiency across various industries. The advancements in design will not only enhance performance but also optimize logistics and supply chain operations. Key technical specifications, such as increased load capacity, reduced weight, and innovative materials, are central to these advancements. For instance, spools made from advanced composite materials can provide greater durability and strength while being lighter than traditional steel options, allowing for easier handling and transportation.

Moreover, the integration of smart technology into steel cable spool design is becoming a game-changer. Features such as built-in sensors and IoT connectivity will facilitate real-time tracking and monitoring of cable usage. This intelligent approach will enable companies to forecast demand accurately and streamline procurement processes, minimizing waste and reducing downtime. As businesses adapt to these trends, they will find themselves better equipped to respond to the dynamic market demands, leading to enhanced operational efficiency and cost savings.

Trends in Steel Cable Spool Technology for 2025

This chart illustrates the projected advancements in technical specifications for steel cable spools, highlighting key dimensions such as tensile strength, weight reduction, and manufacturing efficiency. The data reflects trends from industry research on procurement efficiency over the next few years.

Comparative Analysis of Steel Cable Spool Materials: Strength, Durability, and Cost Efficiency

In the evolving landscape of manufacturing and logistics, the choice of materials for steel cable spools plays a crucial role in determining product strength, durability, and cost efficiency. Traditional steel spools, while highly durable and strong, often come with substantial weight and higher production costs. Innovations in material science have led to the development of composite materials and advanced alloys that can offer comparable strength while significantly reducing overall weight. This shift not only enhances handling efficiency in transportation but also positively impacts fuel consumption during transit.

Cost efficiency remains a pivotal factor in procurement decisions, especially amidst fluctuating global markets. While steel spools may initially appear cheaper, total cost ownership must be considered: factors such as maintenance, lifespan, and replacement costs can skew the economics in favor of premium materials that require less frequent replacement and are more resilient to wear and tear. As companies strive for sustainability and reduced operational costs, a comparative analysis of these materials reveals that investing in higher-quality, advanced spool technologies could ultimately lead to enhanced procurement efficiency and long-term savings.

Influence of Automation and Smart Technology on Steel Cable Spool Production Rates

The evolution of automation and smart technology in steel cable spool production is set to revolutionize the industry by significantly enhancing production rates. With advancements such as robotic arms and AI-driven quality control systems, manufacturers are witnessing unprecedented efficiency gains. These automated processes not only minimize human error but also ensure consistent quality, enabling factories to scale up operations to meet growing global demand.

Moreover, the integration of smart technology, such as IoT sensors, provides real-time data monitoring on production lines. This capability allows for proactive maintenance and immediate adjustments to manufacturing processes, reducing downtime and optimizing resource usage. As supply chains become increasingly interconnected, maintaining efficiency at every stage of production is crucial. The incorporation of these technologies not only streamlines production but also positions businesses to better respond to market fluctuations and client needs in an ever-competitive landscape.

Global Market Trends: Shifts in Steel Cable Spool Procurement Strategies and Supplier Selection

The procurement landscape for steel cable spools is evolving rapidly as organizations adjust their strategies to enhance efficiency and responsiveness. Emerging trends in supplier selection highlight a shift towards more sustainable and innovative sourcing practices. Companies are increasingly favoring suppliers that not only offer high-quality products but also demonstrate a commitment to eco-friendly manufacturing processes. This is partially driven by increased regulatory scrutiny and a growing emphasis on corporate social responsibility within global supply chains.

Additionally, geopolitical factors have significantly influenced procurement strategies. Recent discussions, such as the public hearing on the Section 232 investigation of steel imports, underscore the importance of national security considerations in the procurement process. As countries like the United States evaluate their steel supply chains, global buyers must adapt to these dynamics by diversifying their sourcing channels and establishing relationships with reliable suppliers in different regions. The focus on supplier resilience and compliance with emerging regulations will be crucial in shaping the future of steel cable spool procurement strategies.

Emerging Sustainability Practices in Steel Cable Spool Manufacturing: Impact on Procurement Efficiency

In recent years, sustainability practices have become increasingly crucial in the steel cable spool manufacturing industry. Companies are adopting innovative techniques that not only minimize environmental impact but also enhance procurement efficiency. By integrating eco-friendly materials and energy-efficient processes, manufacturers can produce steel cable spools that align with global sustainability goals. This shift not only meets buyer expectations for environmentally responsible products but can also lead to cost savings in the long term.

Tip: When considering suppliers, prioritize those who demonstrate a commitment to sustainable practices. Request information about their manufacturing processes, and look for certifications that validate their environmental efforts. This can also streamline your procurement process by ensuring you partner with manufacturers focused on efficiency.

Moreover, many manufacturers are now leveraging advanced technologies like automation and AI in their production lines. These technologies not only improve the quality and consistency of the steel cable spools but also enable faster turnaround times, directly impacting the efficiency of procurement strategies. Companies can respond more swiftly to market demands, reducing lead times and improving inventory management.

Tip: Embrace digital tools for monitoring and managing your supply chain. Real-time data on inventory levels and production schedules can help you make informed purchasing decisions, ensuring you never face delays or shortages.

Exploring the 2025 Trends in Steel Cable Spool Technology and Their Impact on Global Procurement Efficiency

| Dimension | 2025 Projection | Impact on Procurement | Sustainability Practice |

|---|---|---|---|

| Smart Spool Technology | Enhanced tracking and monitoring capabilities | Increased transparency and efficiency in logistics | IoT integration for reduced waste |

| Eco-friendly Materials | 30% increase in recyclable material usage | Lower costs through waste reduction | Use of bio-based resins in spools |

| Automated Production | 50% efficiency increase in manufacturing | Faster turnaround times and lower labor costs | Reduced energy consumption in production |

| Data Analytics | Real-time analytics for supply chain management | Enhanced decision-making processes | Optimizing resource usage based on data |

| Waste Management | Significant reduction in production waste | Cost savings through recycling initiatives | Implementing circular economy practices |