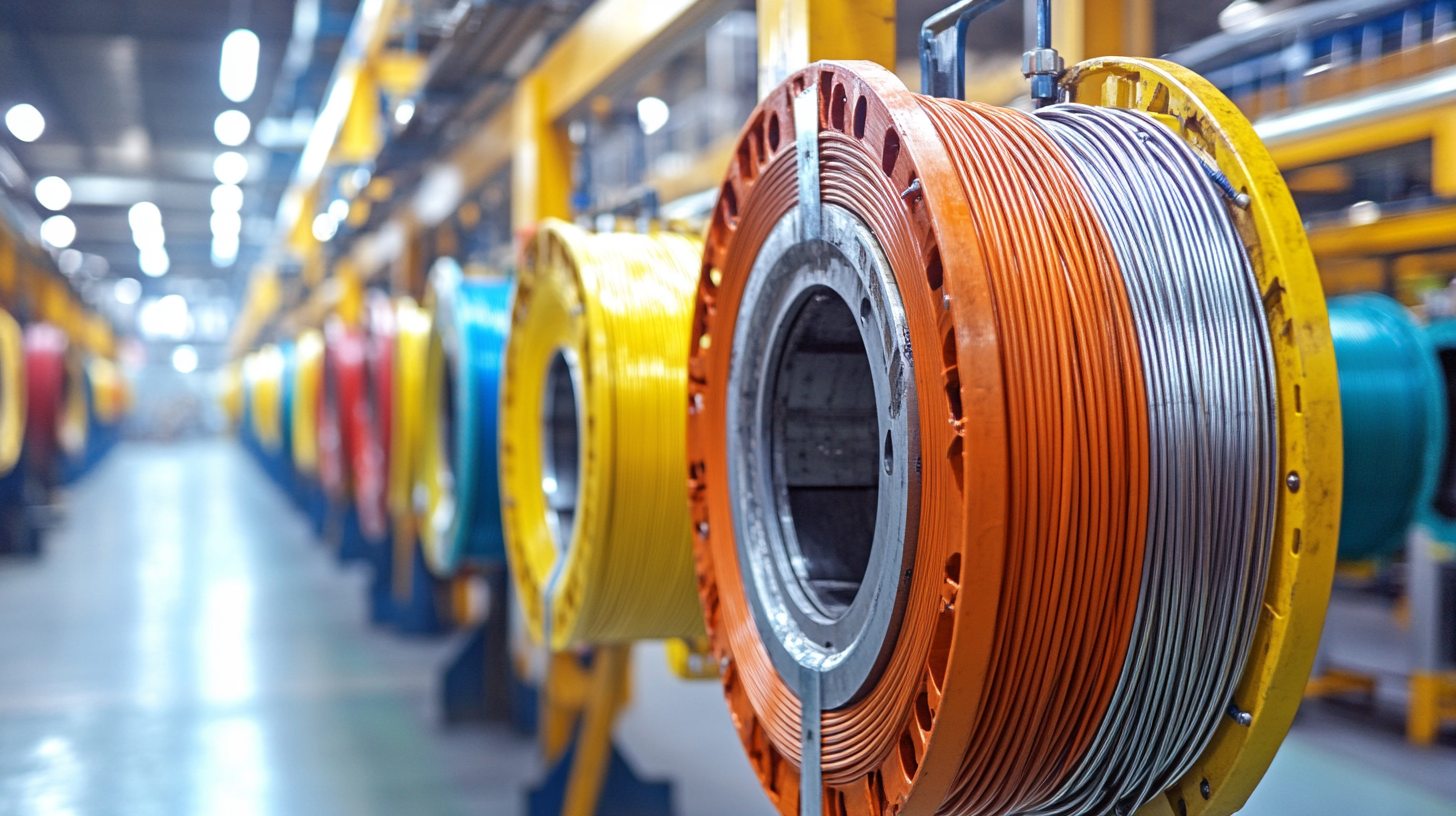

Ultimate Examples of Best Steel Cable Spool Designs for Global Buyers

In the world of manufacturing and logistics, the design of components plays a critical role in the efficiency and effectiveness of operations. One such essential component is the Steel Cable Spool, which serves as a vital tool for organizing, storing, and facilitating the smooth deployment of steel cables in various industries. As global buyers seek top-notch solutions for their cable management needs, understanding the diverse designs and functionalities of Steel Cable Spools becomes paramount.

This blog aims to explore the ultimate examples of the best Steel Cable Spool designs, showcasing innovative strategies that enhance performance and usability. From robust construction and ergonomic features to specialized designs for unique applications, we will highlight the key elements that make these Steel Cable Spools stand out, providing valuable insights for buyers looking to invest in reliable and efficient solutions.

Join us as we delve into the world of Steel Cable Spools and discover the top strategies that can revolutionize your cable handling processes.

Innovative Steel Cable Spool Designs: A Global Market Perspective

Steel cable spools play a crucial role in various industries, from telecommunications to construction, and their designs have evolved significantly to meet global demands. Innovative designs focus not only on functionality but also on optimizing storage and transportation. For instance, spools with modular features allow for easy stacking and reduced storage space, making them ideal for manufacturers and suppliers looking to enhance logistics efficiency around the world.

Furthermore, sustainability has become a key consideration in the steel cable spool market. Manufacturers are increasingly using recycled materials and designing spools that can be repurposed at the end of their lifecycle. This shift not only appeals to environmentally-conscious buyers but also aligns with global initiatives aimed at reducing waste.

As industries worldwide continue to push for more sustainable practices, the steel cable spool designs that prioritize eco-friendliness are gaining traction, reflecting a broader trend in the global market.

Key Features of High-Performance Steel Cable Spools for Various Applications

When it comes to high-performance steel cable spools, a few key features set the best designs apart for global buyers. First and foremost, durability is essential. Steel cable spools must withstand heavy loads and weather conditions without compromising their structural integrity. Robust construction materials, such as zinc-coated or stainless steel, enhance resistance to corrosion, ensuring longevity even in the most demanding environments.

Another important aspect is the design for ease of use. Features like ergonomic handles or integrated wheels can significantly improve handling and maneuverability, which is crucial for professionals working in construction, electrical installations, or telecommunications. Additionally, spools engineered with smooth rolling systems help prevent cable tangling and promote efficient unwinding and rewinding, making them ideal for fast-paced applications. With customizable options for size and capacity, these spools cater to an array of industrial needs, making them a versatile choice for various applications globally.

Comparative Analysis: Material Strength and Durability in Steel Cable Spools

When it comes to selecting the best steel cable spools, understanding the material's strength and durability is paramount. Steel cable spools are essential components in various industrial applications, where the integrity of the materials directly affects performance. The comparative analysis of different steel grades reveals significant differences in characteristics such as elasticity, tensile strength, and resistance to corrosion. For instance, high-strength steel spools offer superior durability under extreme conditions, making them ideal for heavy-duty uses.

**Tips:** When choosing steel cable spools, consider the environmental conditions they will be exposed to. Opt for galvanized or stainless steel options if moisture is a concern, as these materials provide additional resistance to rust and degradation. Additionally, examining the spool's design can influence its effectiveness—look for features that minimize wear and enhance load distribution.

Another aspect to consider is the manufacturing process of these spools. For example, advancements in welding techniques, such as optimizing TIG welding parameters, can enhance the overall strength of the joint where components are joined. This attention to detail ensures that the steel cable spools not only meet but exceed operational demands. By making informed choices based on material and construction methods, global buyers can ensure they select spools that reliable and efficient for their specific needs.

Sustainability Trends in Steel Cable Spool Manufacturing and Usage

In the realm of steel cable spool manufacturing, sustainability has become a crucial focus, reflecting a shift towards more eco-friendly practices. Manufacturers are increasingly adopting recycled materials in their production processes, which not only reduces waste but also lowers the carbon footprint associated with new raw materials. This trend not only conserves resources but also appeals to environmentally conscious consumers looking for sustainable options in their purchasing decisions.

Tips for Sustainable Steel Cable Spool Usage:

- Opt for spools made from recycled steel to minimize environmental impact. This choice supports circular economy principles and encourages further recycling initiatives.

- Consider the durability of the spools. Investing in high-quality, long-lasting products can reduce the frequency of replacements, thereby conserving resources over time.

Moreover, innovative companies are now exploring biodegradable coatings and finishes for steel spools, enhancing their lifecycle while ensuring they remain functional in demanding environments. As global buyers prioritize sustainability, the industry is likely to continue evolving, fostering a greener future in steel cable spool production and consumption.

Tips for Future-Proofing Your Purchases:

- Stay informed about manufacturers' sustainability practices. Research companies that are transparent about their environmental efforts and make conscious buying decisions.

- Engage with suppliers who are willing to share their sustainability certifications to ensure you are supporting responsible practices.

Impact of Design on Operational Efficiency and Safety Standards in Cable Handling

The design of steel cable spools plays a critical role in enhancing operational efficiency and maintaining safety standards in cable handling practices. Innovative designs that incorporate features such as reduced weight, ergonomic shapes, and improved coil geometry can significantly affect how cables are stored, transported, and deployed. For instance, spools designed with easy-grip handles facilitate seamless maneuvering, allowing workers to handle heavy cables with minimal strain. This not only boosts productivity but also reduces the risk of injuries common in cable handling tasks.

Moreover, the integration of safety features in spool designs, such as stable bases and locking mechanisms, ensures that cables are securely stored and minimize the chances of accidents during transport. Well-designed spools can prevent tangling and damage to the cable, further enhancing operational reliability. Manufacturers are increasingly focusing on materials and designs that promote durability and resilience, which ultimately contributes to cost savings and improves compliance with industry safety standards. By prioritizing thoughtful design in steel cable spools, companies can greatly enhance their operational workflows and protect their workforce.

English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик